Quality Inspection

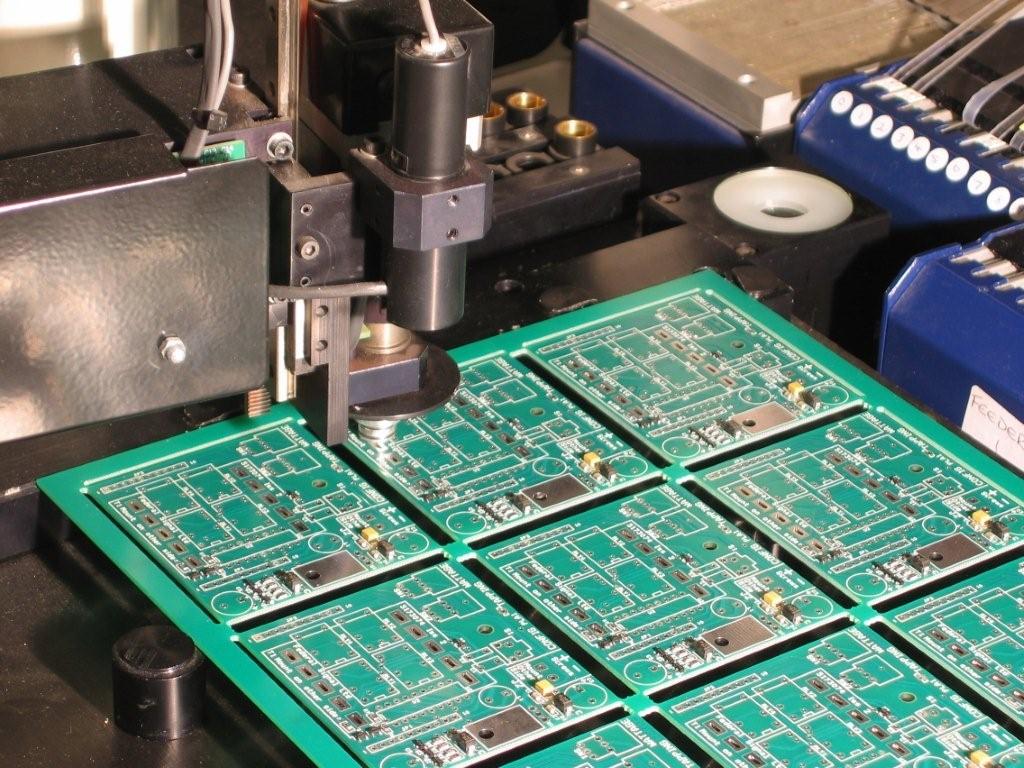

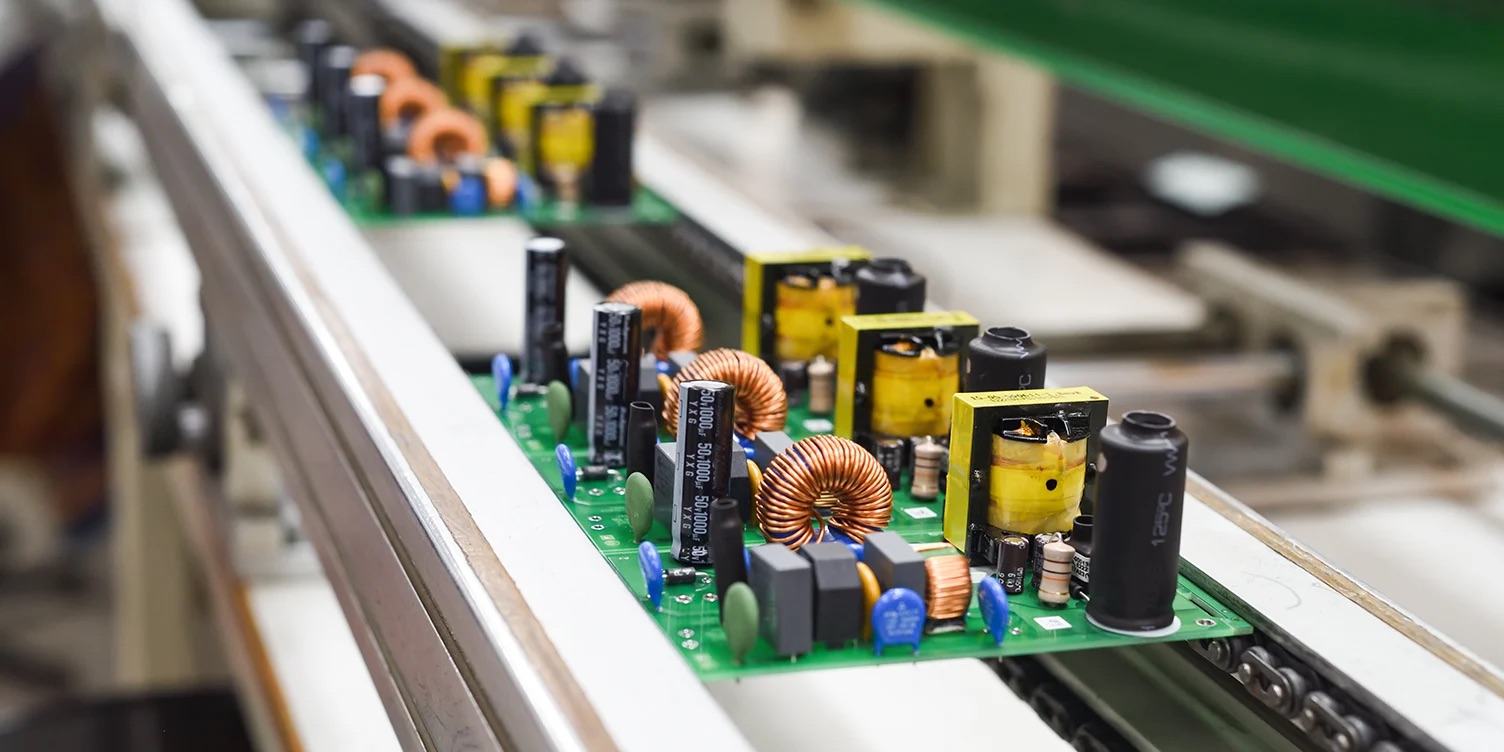

We use advanced MES for production line control ,with Fuji NXT,MPM, JUKI, Desen, Suneast and other industry professional equipment, which covers automatic surface mount system , reflow soldering, automatic testing and packaging processes,and production workshop using a fully enclosed air-conditioning system ,temperature and humidity and lighting intensity control ,high standards of electrostatic protection managerment.

98%

99%

-

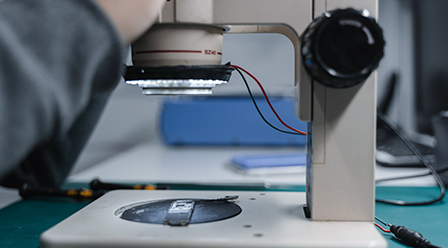

Visual inspection

-

X-ray Inspection

-

3D AOI Testing

-

ICT (In-Circuit Test)

-

FAI

-

AOI Testing

-

3D SPI Testing

-

Functional Test

Visual inspection

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

X-ray Inspection

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

3D AOI Testing

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

ICT (In-Circuit Test)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

FAI

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

AOI Testing

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

3D SPI Testing

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

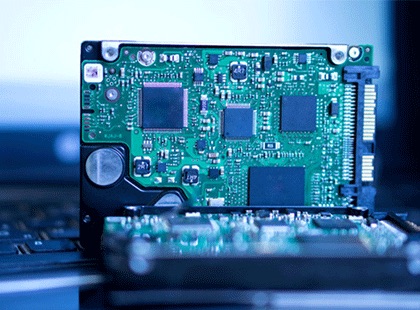

Functional Test

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.

| Order Qty | Component Qty per board | Visual Inspection | AOI |

|---|---|---|---|

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

| Q<=10< /td> | N/A | Yes | No |

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is a tool in circuit board assembly to efficiently and accurately detect production errors before boards leave the facility. AOI uses cameras and image processing software to identify assembly errors such as missing or misplaced components, identifying short circuits, and disconnected components. With more complex boards and larger production quantity this tool improves error detection over visual inspection. AOI machines have seen widespread adoption as surface mount components have miniaturized and board production aims to be more efficient.

At Bittele Electronics AOI is one tool we use to provide the best product quality to our turn-key customers. Due to the added labor of setting up the AOI equipment, it is more economical for our clients if we conduct this type of inspection on larger or complex orders as listed in the table below. All of our work is visually inspected by our quality assurance technicians. There is no additional cost when AOI is used, as it is included in our standard assembly services as directed below.